Technology

The BioRefinex Thermal Hydrolysis Process

The BioRefinex Thermal Hydrolysis Process

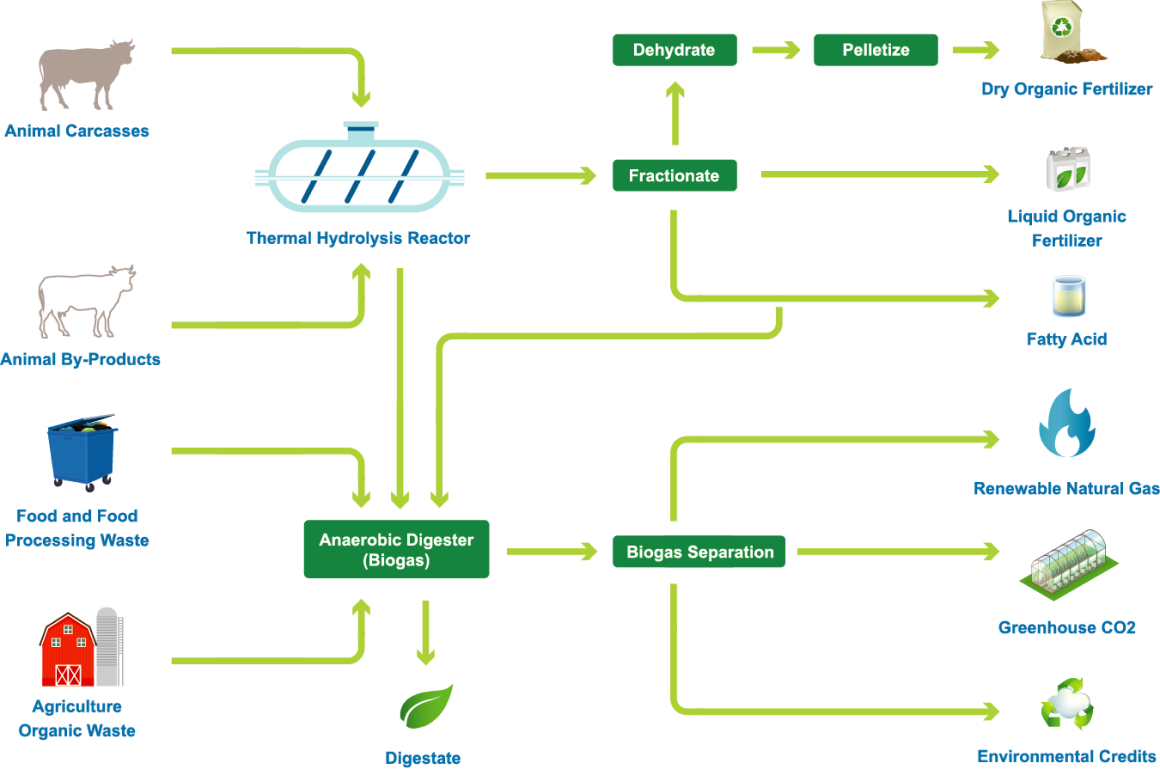

At the core of the patented BioRefinex process (patents and patents pending in over 20 countries) is the BioRefinex “Thermal Hydrolysis Reactor”, which uses high pressure and saturated steam to denature all organic material and destroy all pathogens while retaining the valuable nutrients.

The hydrolyzed output is then fractionated using a series of centrifuges to maximize value and to produce consistent streams of organic fertilizer and nutrient feedstock for biogas production.

The facility also provides the overall biorefinery service of receiving and processing waste material that otherwise would be sent to landfills, in exchange for tipping fees.

Hydrolysis is a chemical process in which a certain molecule is split into two parts by the addition of a molecule of water. The process forces the water molecules between the chemical bonds holding large tissue molecules such as fats, DNA and proteins together. Thermal hydrolysis uses a combination of high temperature and high pressure to break the tissue down to their original small molecular building blocks resulting in a dramatic reduction in viscosity, the destruction of all infectious agents (including TSEs) and the increase of biodegradability.

The first phase in the anaerobic digestion process is hydrolysis. In a conventional digester, the entire process begins with bacterial hydrolysis of the inputs. Using the BioRefinex process, this lengthy first step has been completed prior to material entering the digester resulting in shorter retention times and higher destruction rates. Biogas is typically rich in methane and low in H2S.